What Is A HACCP Plan? Everything You Need To Know For Your Food Business In 2025.

You’ve heard the term HACCP and know that you need to somehow incorporate it into your food business. But how, what, why and when?

There’s a lot of information out there and to be honest, it can be a little confusing trying to find out how it applies specifically to hospitality businesses.

We’ve got you covered with this guide covering what HACCP is all about and how to implement it in your food business.

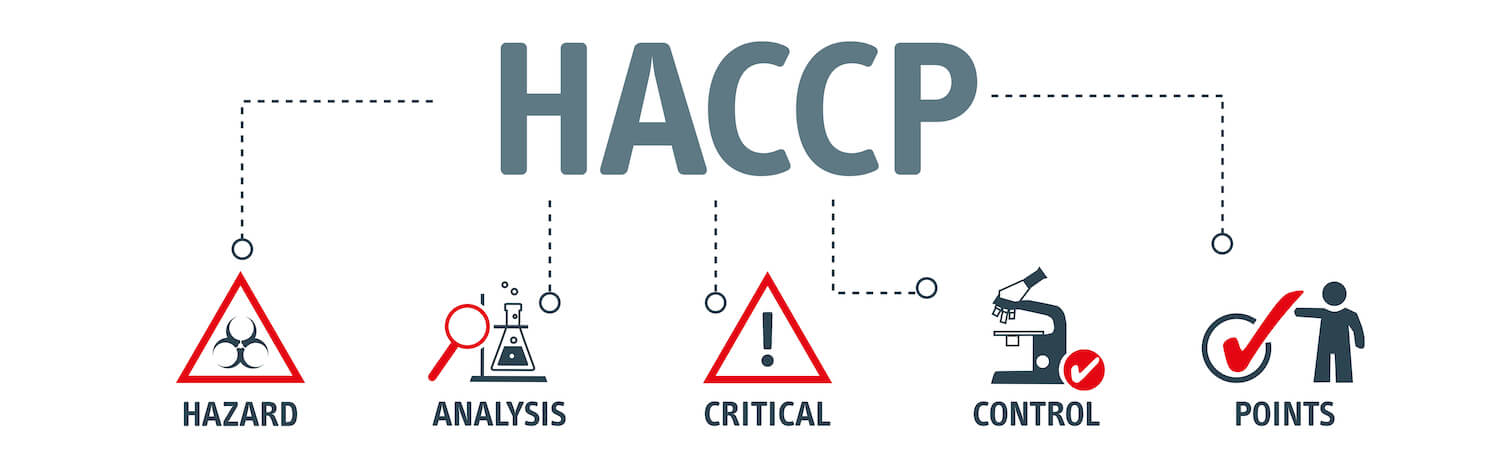

What is HACCP?

HACCP stands for Hazard Analysis Critical Control Point and is an internationally recognised standard (ISO 22000 FSMS 2011) of managing food safety risk. It is a total management system that looks at the analysis and control of biological, chemical, and physical hazards from raw material production, procurement and handling, to manufacturing, distribution and consumption of the finished product.

Simply put, it is a really effective system that ensures that food products are safe to eat.

Globally, hospitality establishments use HACCP as the basis of their food safety plans providing customers and verifiers/auditors assurance that a food safety plan is well managed.

Why is HACCP so important to hospitality businesses and the food industry?

If you aren't a cafe or restaurant, food may not be the core part of your business. Perhaps you are a child care centre, hotel, petrol station, or aged care facility where food is a service that you offer. Or a company which has a cafe for your staff. Either way, if you are preparing or serving food in any capacity you will need to be following proper food safety protocols to ensure the health and safety of your customers and staff.

Contaminated food can be hugely damaging. Aside from affecting a person's health and well-being, there is the potential damage to your business reputation and brand.

If you think about all that is involved with creating a meal - from supplier ordering to receiving goods, storage, prepping, cooking, cool down and handling, we realise how many opportunities there are to introduce harmful bacteria, placing food at risk. HACCP addresses all of these points helping us to identify, control and minimise risks.

Many hospitality businesses use HACCP as a key part of their food safety management system to conduct risk assessments and manage potential hazards in the kitchen.

Having a HACCP plan in place will help you create a positive food safety culture and a successful food business. Customers will know your food is safe and it will reduce the likelihood of customer complaints.

What is a HACCP Plan?

A HACCP plan is a document based on the 7 principles of HACCP which addresses all of the different aspects of your food business including food handling and preparation. This plan should be managed and reviewed on a periodic basis to make sure that it continues to be effective. The kitchen team should have a good understanding of the plan and be active in the recording and management of it.

What are the 7 steps of HACCP?

HACCP is based on seven key principles. These principles are designed to identify, evaluate and control food safety hazards.

- Conduct a hazard analysis.

- Determine the critical control points (CCPs).

- Establish critical limits.

- Establish monitoring procedures.

- Establish corrective actions.

- Establish verification procedures.

- Establish record-keeping and documentation procedures.

1. Conduct a hazard analysis

The first step of creating your HACCP plan is to identify potential hazards in your kitchen. It’s similar to a risk analysis - you’re looking for any issues that might arise from the handling or processing of food that could lead to injury or illness. HACCP categorises these hazards into three areas: physical hazards, biological hazards and chemical hazards.

An example of a potential hazard is receiving cold goods from a supplier.

2. Determine the critical control points

A critical control point is where action can be taken to prevent or eliminate a food safety hazard or reduce it to an acceptable level. Each hazard that you identify in the step above, will have at least one critical control point.

Using the example above, the critical control point would be to check the temperature of refrigerated goods as they are being delivered.

3. Establish critical limits

The critical limit is the measurement you will use for each hazard. Once you have identified a hazard and determined how you will prevent this hazard from occurring, you will need to document the point at which the risk is deemed acceptable, and the point at which action needs to be taken. Some risks may have multiple critical limits such as cooling and cooking temperatures for meat.

Using the example of receiving chilled goods from a supplier, the critical limit here would be that the goods are tested upon receipt and are 5 degrees or cooler.

4. Establish monitoring procedures

It’s important to have a method to monitor and record your procedures so that you can make sure that issues are identified and action is taken quickly to fix them. Monitoring will allow you to assess that a critical control point is under control and will give you an accurate record for future use in verifications and audits.

Records can be digital or on paper. Of course, we suggest using a digital food safety app to save time and make monitoring efficient. You can also use automated fridge temperature monitoring, giving you a hands off way to constantly monitor and record your refrigeration temperatures. By establishing your critical limits, you’ll get alerts if your temperatures fall outside of this range.

In our example, the monitoring procedure might be to test and record one item out of each chilled delivery.

5. Establish corrective actions

What happens when you identify an issue? A corrective action needs to be put in place. If an issue comes up where the critical limit has been exceeded, what needs to be done to correct this? If this issue occurs frequently, then what needs to change with procedure and measurement to ensure that this problem doesn’t happen again?

In our example, if chilled goods received were tested to be above 5 degrees, the corrective action would be to not accept the goods and to address this with your supplier. Should you notice that this situation was occurring frequently with a particular supplier then you would look at sourcing the goods from an alternative supplier.

6. Establish verification procedures

Verification is an ongoing process to ensure that your system is operating according to the plan. HACCP is designed to prevent, eliminate, or reduce the occurrence of food safety risks. It works as a continual loop which means reviewing and improving your processes ongoing.

Is your monitoring and action plan working to ensure food safety? Look at setting up intervals to review your records and check your tools (such as calibrating thermometers). If areas of concern are identified, review of your processes and monitoring methods to see where you can improve.

7. Establish record-keeping and documentation procedures

The final step in the HACCP plan is making sure that you have good record keeping and documentation for all of the above steps.

This includes a copy of your food safety plan, how you have been monitoring potential hazards, records of monitoring and actions taken when required. Again, using digital food safety software is an excellent way to collate all of this information on hand with the ability to access it from anywhere at any time. In addition, if you are still keeping paper records, there is a risk that they may get damaged or lost. Using an app like Chomp, your records are stored securely in a cloud where you can access them easily.

Who needs a HACCP plan? Is a HACCP plan mandatory?

HACCP is useful in all kitchens no matter how big or small. If you are serving, producing or handling food, it is relevant.

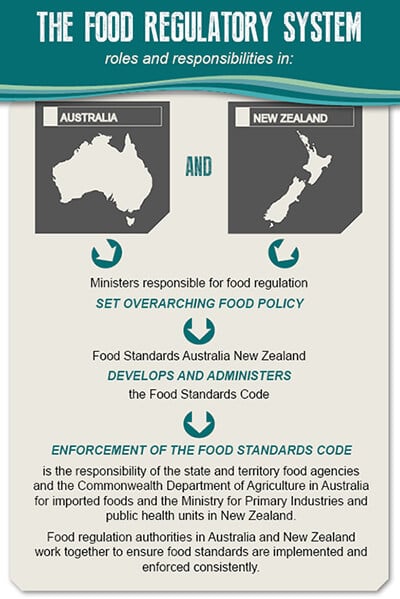

In some countries, HACCP is required by law. In New Zealand and Australia, food safety is governed by FSANZ which stands for Food Safety Australia New Zealand.

FSANZ develops the food standards in the Food Standards Code which sets legal requirements for the labelling, composition, safety, handling, and primary production and processing of food.

Food Standards Australia New Zealand

It is a requirement for all food businesses to have a documented Food Control Plan in New Zealand and in some states of Australia, a Food Safety System, both of which are based on HACCP principles. A food control plan (New Zealand) or food safety system (Australia) shows what steps you are taking to make safe food. It is used to identify risks and show how they're being managed.

They are both the same but referred to differently in each country.

Is a HACCP plan mandatory in New Zealand and Australia?

In New Zealand, the application of HACCP to your food control plan is mandatory under the Food Act 2014. This means that all commercial kitchens have to have a food control plan.

In Australia, the standards in the Food Standards Code are legislative instruments under the Legislation Act 2003. The authoritative versions of these standards are on the Australian Government Federal Register of Legislation.

Currently in Australia, at a national level, only certain high risk food businesses are required to have food safety programs such as aged care, child care and hospitals.

However, food businesses may be required to have food safety programs under state or territory food legislation. Check your state/territory requirements with your local council or state/territory health department.

As with New Zealand, food safety programs are also based on HACCP.

Conclusion

Having a food control plan or food safety system should be seen as a necessary and essential part of your food business. Having a system in place, will keep your customers safe, your employees safe and ensure that your kitchen is working to a high standard and delivering quality food. In addition, having a food safety system will help to protect your brand reputation and reduce customer complaints.

Although HACCP is not mandatory in many countries, it is a tried, tested and trusted methodology. You can use it as a template for creating your food safety plan by applying the 7 HACCP principles as much as possible in relation to all aspects of food preparation and handling within your kitchen.

Our Chomp digital food safety app follows and integrates with HACCP principles. Critical control points and limits can be set, monitored and recorded in real time. The app will prompt for information if any corrective action needs to be taken and document it. When audit time comes, reports can be sent to verifiers at the click of a button with all the information needed.