In any food business, temperature fluctuations can affect the safety and quality of food stored in fridges or freezers.

The Importance of Accurate Temperature Monitoring for Fridges and Freezers

Making sure that food is kept at the right temperature will prevent bugs from growing quickly. Certain foods must be kept cold, either chilled or frozen, to prevent bugs from growing resulting in food spoilage.

There are some foods which need to be kept cold to keep them safe such as milk and meat, and there are some foods which are best kept cold for customer enjoyment like white wine and kombucha! It's important to know the difference between the two, making sure that the foods that need to be kept cold are stored at the correct temperatures.

To ensure that food is stored at the correct temperature, accurate temperature measurements in fridges and freezers is crucial for any restaurant or cafe.

Why the temperature displayed by fridges and freezers isn't good enough

Relying solely on temperature displays on fridges and freezers can be misleading as there are several things that can affect their accuracy. The three main issues are:

- Fluctuations in room temperature

- Improper calibration

- Measuring air temperature

1. Fluctuations in room temperature

Changes in room temperature can have a huge impact on the accuracy of temperature readings in fridges and freezers. These fluctuations can occur for loads of reasons such as changes in kitchen temps, opening and closing of doors, and the proximity of the fridge/freezer to heat sources.

When the room temperature fluctuates, the internal temperature of the fridge or freezer may also change, causing the temperature display to show an inaccurate readings. This can be a major concern for any food business as it can compromise the safety and quality of the stored food. To ensure accurate temperature monitoring, relying solely on the temperature display is not enough.

2. Improper calibration

Proper calibration of temperature displays on fridges and freezers can be tricky depending on the type of fridge or freezer and requires constant attention and monitoring. In addition, the fluctuations in room temperature (mentioned above) and the measurement of air temperature (mentioned below), make it an unreliable method for accurately measuring the true temperature.

3. Measuring air temperature

Measuring air temperature is not considered a reliable method in a food business as air temperature can fluctuate with defrost cycles of a fridge, frequent opening and closing of doors, air circulation patterns and location in the kitchen, just to name a few. This leads to inaccuracy as the temperature reading won't necessarily be the same as the temperature of the produce that is being stored.

Food safety compliance for hospitality businesses

MPI (Ministry of Prime Industries) states in the Simply Safe & Suitable Food Control Plan:

"You need to make sure that temperature monitoring equipment (e.g. thermometers) are accurate (i.e. calibrated).

You cannot rely on the temperature shown on your fridge/chiller."

MPI allows three suitable ways to monitor the temperature food in a fridge:

- Using a calibrated probe thermometer to check the temperature of food or other substance (e.g. a container of water)

- Using a calibrated infrared thermometer to measure the surface temperature of the food

- Using a calibrated automated system (e.g. bluetooth temperature monitoring system) to monitor the internal temperature or surface temperature of your food.

The best way to accurately measure fridge and freezer temperatures

The most accurate way for a hospitality businesses to measure fridge and freezer temps is through a system that uses a temperature probe to measure mass (not air). Temperature probes are specifically designed to prevent incorrect readings by protecting the thermometer from sudden changes in temperature.

The temperature probe is placed in a liquid or other matter (also called temperature buffering) to provide the most accurate reading as this mimics the temperature of mass (food and liquids) rather than just measuring air temperature. A temperature buffer reduces temperature fluctuations helping to eliminate any false alerts.

Glycol and glass beads are the most commonly used buffer mediums used with temperature probes. The Center for Disease Control states that glycol-encased probes can provide a more accurate reading of actual temperatures and are therefore recommended.

Aside from this, having glass beads in a cafe or restaurant environment is not a good idea!

The benefits of an automated refrigeration monitoring system

Most councils require that food businesses record fridge and freezer temperatures daily even on closed days.

Whilst this can at first seem inconvenient, the consequences when things go wrong can be huge. Imagine losing all your stock right before a big event due to a fault with your refrigerator, or a power outage or because someone accidentally knocked the plug out of the socket. It happens, sadly we hear it all the time. The stress just isn't worth it, not to mention the wastage and food cost.

Regularly monitoring and recording temperatures allows you to identify any potential issues and take immediate action.

Using a calibrated automated system is a game changer. It's like having a personal security guard watching over your fridges and freezers, notifying you if anything is a bit suspect. These clever pieces of technology called fridge loggers have automated alerts, real-time notifications and will continue to record even when offline.

10 Reasons Why Automated Refrigeration Temperature Monitoring is a Must

How do fridge loggers work?

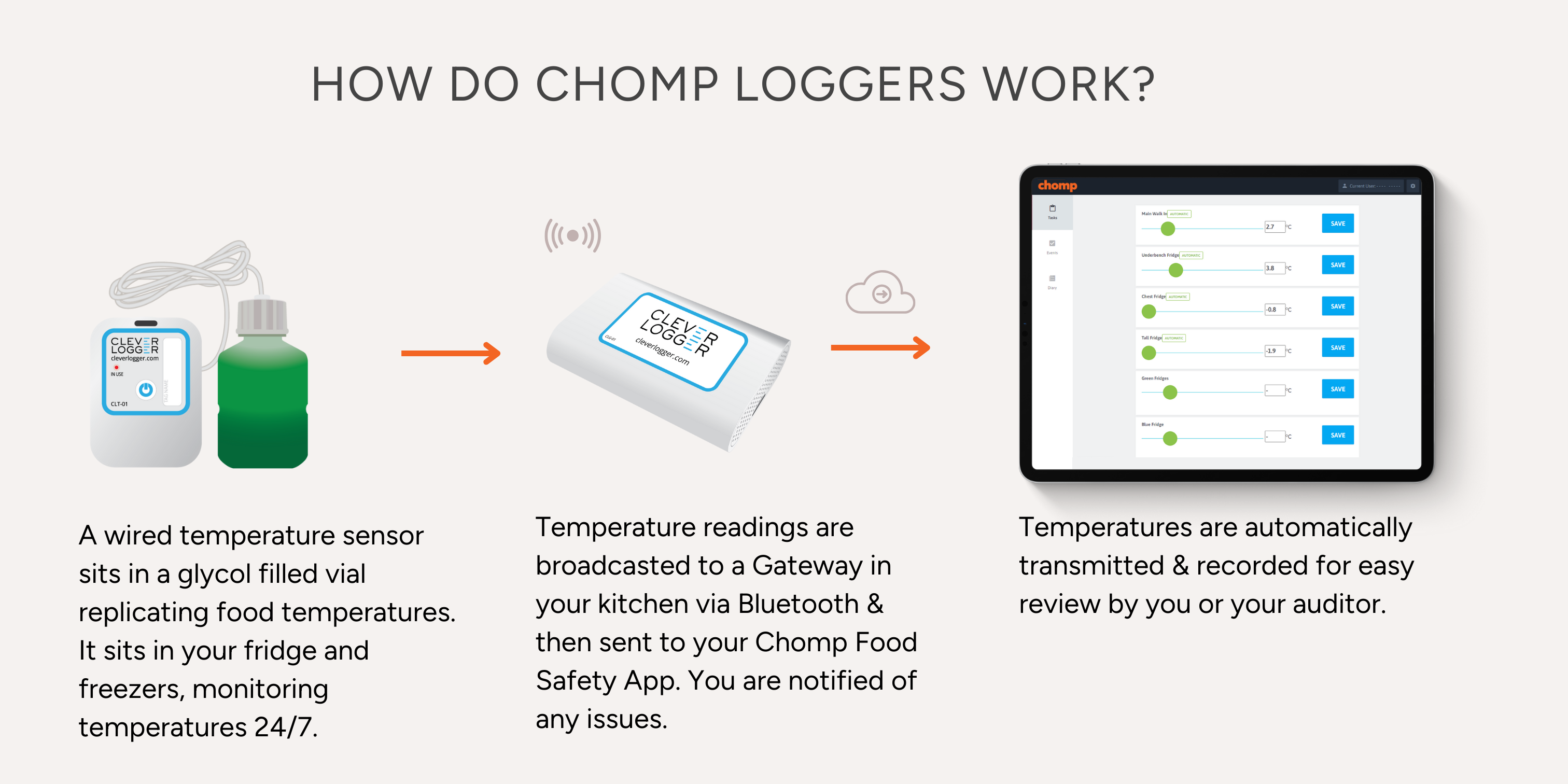

Fridge loggers have a wired temperature sensor that sits in a glycol filled vial. Glycol is used to provide the most accurate reading as it mimics the temperature of mass (food and liquids) rather than just measuring air temperature. The loggers sit in your fridges and freezers, monitoring temperatures 24/7, broadcasting and recording temperature readings to a Gateway located in your kitchen via Bluetooth.

The Gateway receives the temperature readings from the loggers, saving and sending them to your Chomp food safety app or online dashboard. Immediate notifications are sent if there are any potential issues.

If you have Chomp, refrigeration temperatures are automatically recorded for easy review by you or your auditor. Corrective action notes can also be recorded if required. Checking and recording temperatures becomes a piece of cake!

Key takeaways

To summarise, accurate temperature monitoring is crucial for any food business to ensure the safety and quality of stored food in fridges and freezers. Relying solely on temperature displays on fridges and freezers is not enough, as fluctuations in room temperature, improper calibration, and measuring air temperature can affect their accuracy.

To comply with food safety regulations, accepted methods of checking temperatures are calibrated probe thermometers, infrared thermometers, or automated temperature monitoring systems.

An automated refrigeration monitoring system, can provide real-time notifications and continuous recording of temperatures, allowing immediate action to be taken if any issues arise. Investing in this technology not only helps maintain food safety but also minimises wastage and financial loss.

Learn more about the benefits of automated refrigeration temperature monitoring.